The First Moldable, Scalable Infrared Optical Polymer

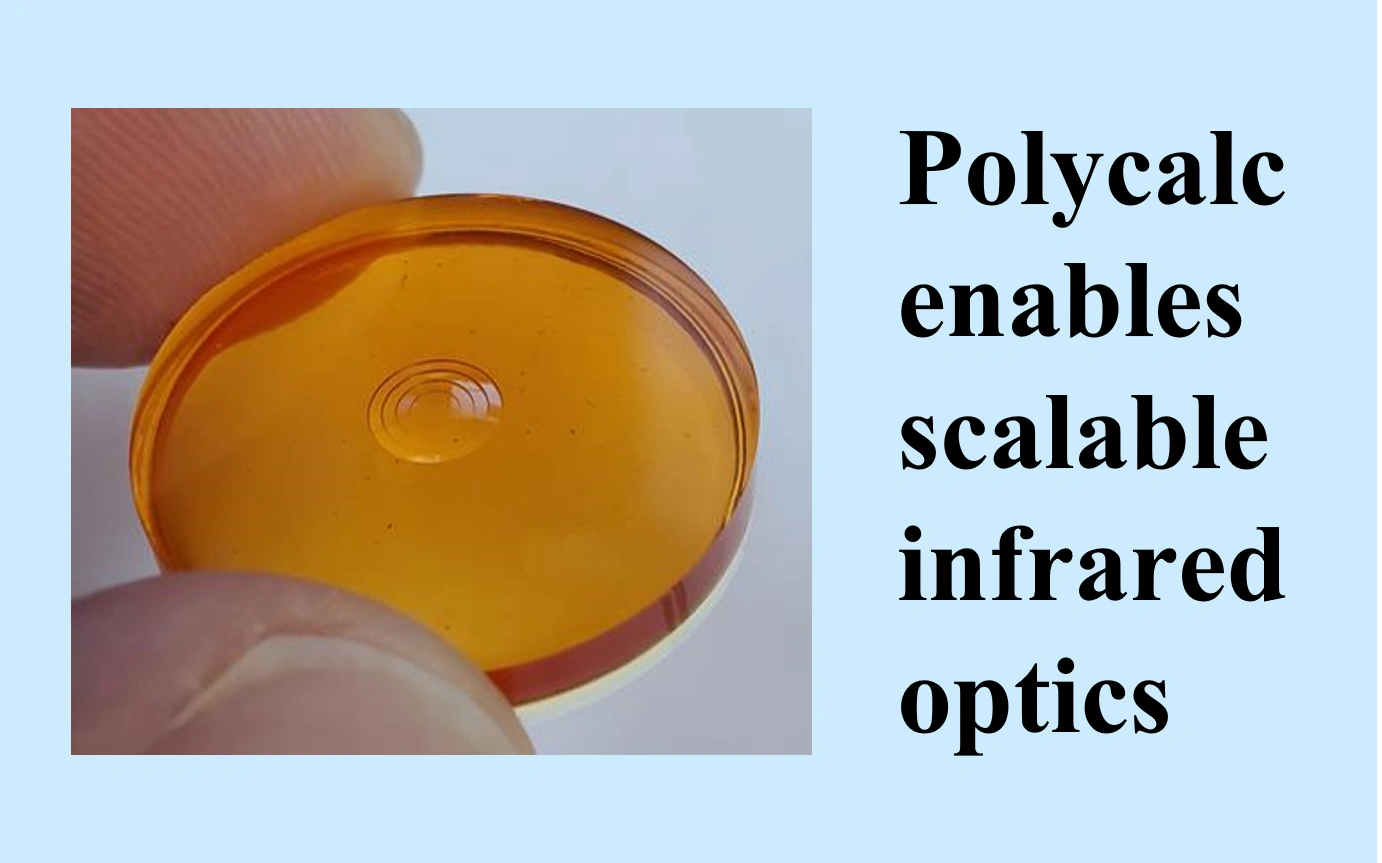

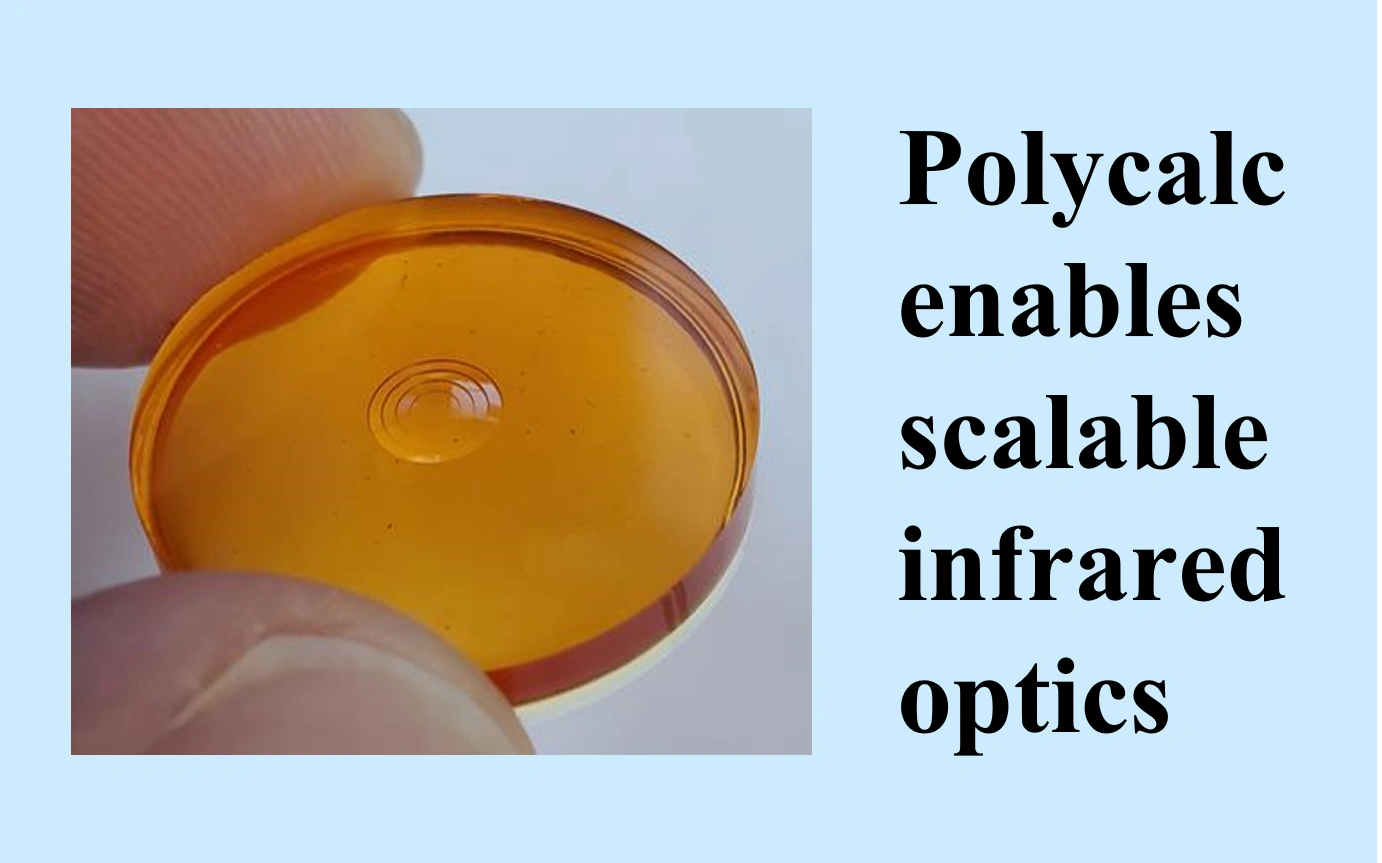

Polycalc is the first infrared optical material that is low cost, moldable, and scalable. This novel material enables infrared sensors to be commoditized for numerous security, health, and safety applications. These include night vision and highway obstacle avoidance, as well as food and drug inspection and respiratory monitoring.

A unique opportunity

Currently, infrared optics are too expensive and fragile to be used outside of applications such as defense and high-end analytical instruments. Applications for infrared optics could be much wider if the optical materials were not brittle glasses that are exceedingly cumbersome to mold and that preclude batch processing. The difficulty in molding compromises focusing ability as complex lens shapes are generally not possible. It also limits mounting features, resulting in long alignment touch times and low assembly yields. In contrast, optical polymers for the visible spectrum are low cost, easily molded, and scalable. Molded polymer lenses produce sharp images and have mounting features that streamline optical assembly. These advantages result in sales that dwarf infrared optics, as polymer lenses for eyeglasses and smartphone cameras are a $175 billion industry.

The benefits of Polycalc

Polycalc is the first polymer optical material specifically designed for the infrared. The infrared properties of our new material come from the same chalcogenide content as found in the glasses mentioned above, where chalcogenides are the Group VI elements in the Periodic Table. The moldability of our polymer derives from the same organic material that has been used to make billions of smartphone lenses. Our intellectual property is in the synthesis of the chalcogen with the organic to achieve a moldable polymer with high infrared transparency. Multi-element designs of complex aspheres, at a fraction of the cost and size of current lenses, become possible for all infrared applications, not just for mobile phones.

Elements with integral flanges

Realize the potential

Combining the best properties of polymers and chalcogenides, Polycalc is transforming infrared sensors. The benefits are profound: focusing becomes sharper; optical assemblies shrink in size; sensor costs plummet. New applications are limited only by your imagination. Contact us to learn how Polycalc infrared optics can help you realize your applications.

Multi-element designs

To learn more

Contact us to explore how moldable Polycalc optics can help your infrared business scale.

Norcon Technologies Holding, Inc.

3333 N. Campbell Avenue, Suite 4, Tucson AZ 85719, USA

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.